Widely accepted as a highly powerful material of the chemical substances, the single crystal nano powder has a wide spectrum of applications especially when it comes to electronic devices. Due to their diameter in nm, single crystal is found to be suitable as building blocks for single-nanoparticle electronic devices.

While studies have shown that nanoparticles produced in low-pressure showcase synthesis better, where large particles were polycrystalline. A new study reports that the single crystal silicon is limited to use only as a constricted, filamentary capacitively coupled plasma (low-pressure) having a diameter of 20-80 nm. The cubic shape of these particles is predominant and hence the distribution is monodisperse.

Talking about the novel devices the silicon crystal silicon nanopowder might be used for, some of these devices are single electron transistors, floating gate memory devices and vertical transistors. The silicon crystal is also found to be of interest in applications of solid state lighting.

For almost 20 years now, nonthermal plasma has been used to produce silicon nanoparticles but from the semiconductor processing and solar cell production a contamination problem was prevalent.

The silicon nanoparticles are apparently tunable in size and this makes the silicon nanocrystals a powerful component that can support functionalities in a wide variety of applications including light emitting devices such as LEDs, molecular electronics, chemical sensors and quantum dot lasers when the element has low toxicity compared to II-IV semiconductors and combined with the existing silicon technology infrastructure in semiconductor industry.

But with the focus on light sources of solid state, the use of silicon nanocrystal could be enhanced. In the long run the silicon nanocrystal could also replace many other light sources light fluorescent bulbs or incandescent light as one of the most energy efficient sources.

The plasma process that can produce these crystals will prove helpful in the future as the use and demand for silicon crystal is going to increase. With plasma synthesis, we should be able to get more highly oriented and defect-free nanoparticles that will have a high monodisperse distribution rate. This synthesis could help with a wider producing of producing qualitative silicon nanopowder that could be used in electronic that run on a nanoparticle mechanism such as the nanoparticle transistors and more.

For more information on silicon nanopowder, here are some properties of this single crystal that you should know:

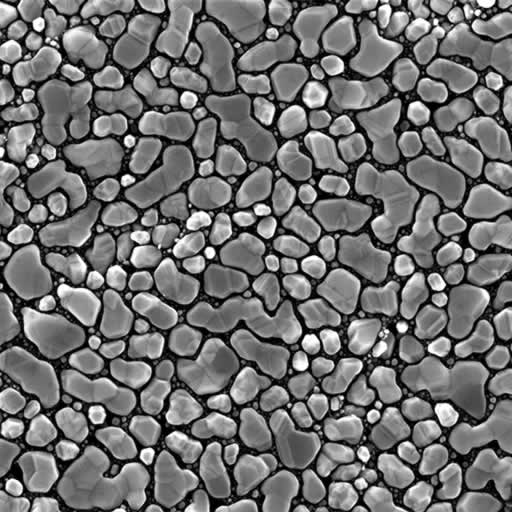

Also called Monocrystal, the single crystal silicon nanopowder has a wide variety of properties. The crystal can be recognized by its evenly colored external appearance. It has a homogeneous crystalline framework and the entire sample is made of unbroken, no grain boundaries.

Another property of this crystal is that it has a rich gray-black color that gives its powder a dark brown finish. It is easily found in abundance as 1/4th of the earth’s crust is made of silicon. But it is not as easily available as one might think. The silicon form found in the environment is more compound form.