Babbitt alloy is widely acknowledged for its soft composition and high thermal conductivity level, when used for manufacturing common bearings. Manufacturers can make the best use of such material for performing bearing repairs, and it can also be used for creating a customizable line of bearings.

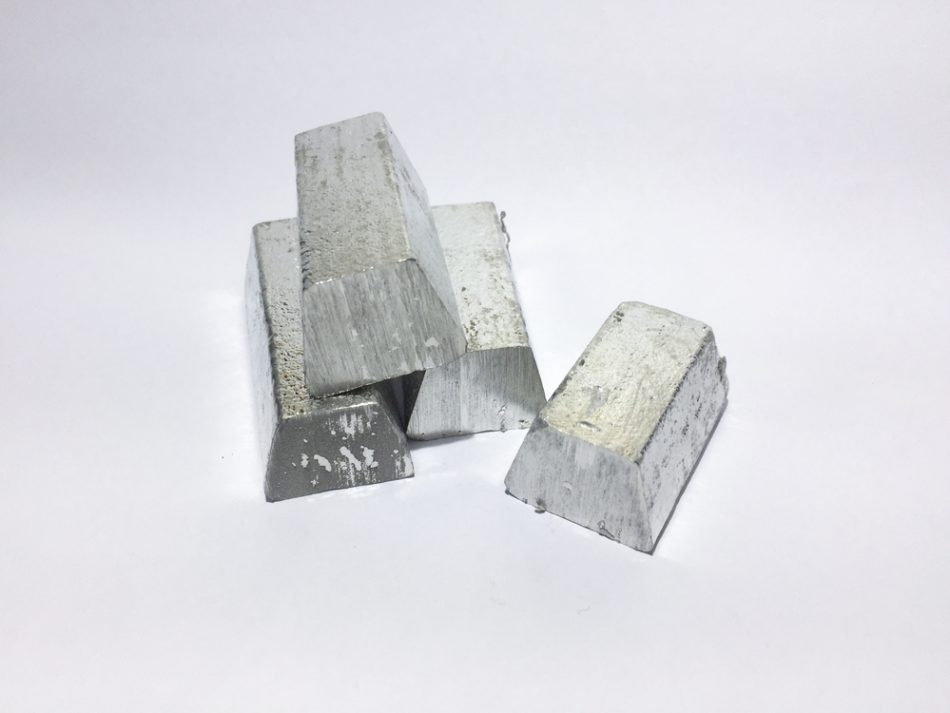

Known as a low melting point alloy, the Babbitt can be further supplemented using bronze, steel, and cast irons due to its extensive forming abilities. The material of Babbitt metal is conformable and pliable, and it does not compromise with its corrosion resistance properties. The metal is equipped to endure heavy loads. It is available in ingots and other components, which can be used widely for manufacturing purposes.

Tin-Based Babbitt

Tin-based Babbitt contains more than 80% of tin alloy, and it also contains traces of lead, copper, and antimony to make up for its remainder composition. Tin-based Babbitt is considered as an excellent option for installing into machinery, which is equipped to transport or prepare foods.

Babbitt metal is widely regarded for its soft composition, and it is often known for being a low melting point alloy. The addition of tin strengthens the integrity of the alloy, which makes it suitable for load-carrying purposes.

Manufacturers are more likely to use tin-based Babbitt for manufacturing common bearings for a number of reasons—two of them being its low wear property along with low friction resistance. The alloy is equipped to perform ideally under a certain percentage of pressure, which makes it a suitable pick for operating the bearings and shafts at a desirable high speed. The tin-based Babbitt is also equipped to gather particles from lubrication systems, which are prone to getting stuck into a metal surface.

Tin-based alloy is further enhanced with its high thermal conductivity properties, and it plays a resourceful role in disabling heat from machinery and equipment. tin-based Babbitt is widely regarded for its high load capabilities, which makes it useful for installing in compressors, marine work, electric motors, and heavy machinery.

Lead-Based Babbitt

Lead-based Babbitt is regarded as a secondary type of material, which encompasses of more than 75% of lead alloy in its composition. It also compromises of low traces of antimony in its composition. The material is widely regarded for its infallible corrosion capabilities, which makes it an excellent fit for manufacturing shipboard essentials. It also plays a vital role in the manufacturing of items, which are prone to high levels of humidity and moisture. Similar to its counterpart tin-based Babbitt, the lead-based Babbitt is also supplemented with excellent frictional capabilities, and it can be further amalgamated to bronze or steel material.

The top characteristics of lead-based Babbitt are exclusive to having excellent conformity, embeddable characteristics, and high thermal conductivity. The use of lead-based Babbitt is considerably ideal for manufacturing items, which can endure a significant amount of shock loads. A substantial number of lead-based Babbitt products are incorporated to low and medium speed machinery. It is also used for manufacturing bearings, which are prone to cyclic loads, unidirectional loads, and light loads respectively.

Also, such type of Babbitt is widely regarded for its affordability and accessibility, and it is commonly used in general machinery, machine shops, and line shafting. In addition, it also plays a vital role in elevator applications, cement machinery, farm machinery, steel mill machinery, and conveyors.