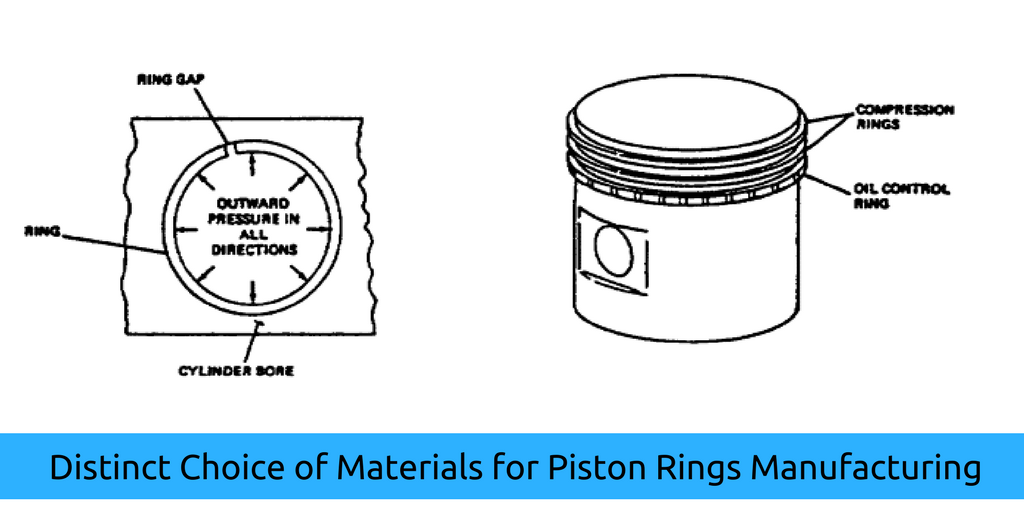

Before moving towards the choice of materials used for manufacturing piston rings, you need to understand the product and its functions. Piston rings are expandable split rings embedded within the grooves on the piston perimeter and mainly perform a list of functions –

- Seal the combustion chamber from the crank case

- Offer uniform oil layer between the cylinder wall and piston, which controls the consumption of oil.

- Transfer the heat from the piston to lower the temperature of cylinder walls

For the different functionalities, experts apply mainly two types of piston rings – compression rings and the oil rings. In major cases, piston rings are crafted using cast iron. Cast iron easily fixed to the cylinder walls. Moreover, cast iron can be easily coated or layered with other materials to make it more durable.

Let’s learn briefly about compression rings and oil rings. A compression ring is closest to the piston head. This ring forms an air-tight seal in between the piston and cylinder wall and seals leakage. It is exposed to the severe conditions in terms of thermal and mechanical loading. Manufacturers usually prefer low alloy, heat treated nodular cast iron with martensitic micro structure for greater hardness.

Oil rings are placed closest to the crankcase. Their function is to regulate the excess oil. It wipes off the extra oil from cylinder walls and revert it to crankcase. Manufacturers of oil rings use unalloyed grey cast iron material for making oil rings. Since grey cast iron has a pearlitic matrix, its modulus of elasticity is low and this ensures good adherence to the cylinder walls.

Piston ring materials are subject to complex system of stressing under dynamic tribiological and mechanical loads. Manufacturers pick the materials ranging from cast irons to steels as per the stresses requirement and their use as compression or oil rings.

Heat treated nodular CI material has high bending strength, while alloyed grey cast iron has increased hardness and wear strength.

Unalloyed grey cast iron is used for oil rings production because this material has a fine-lamellar graphite structure and good conformability because of low modulus of elasticity.

The steel is mainly applied for compression ring material for truck diesel engines, gasoline engines, and steel rails.

You can find out more details on piston rings manufacturing materials online. If you have any query or want to import best quality pistons and rings, contact the premium suppliers today.